Adhesive & Sealant Dispensing

Automated Mobile Robots

Force Sensing

Automated Storage & Retrieval Systems (ASRS)

Force Sensing

Laser Welding

Parts Feeding

Pick & Place

Printed Circuit Board Laser Marker

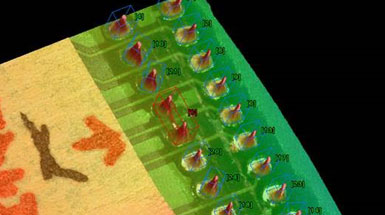

Robotic Inspection & Testing

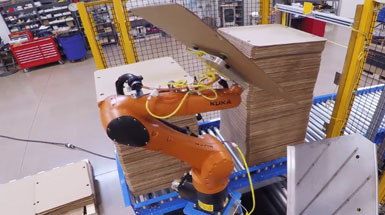

Robotic Palletizing & Depalletizing

Screwdriving

Soldering