Simplimatic Automation Joins Ccam’s Intelligent Flexible Manufacturing Testbed Project Funded By Nist

read more >>>

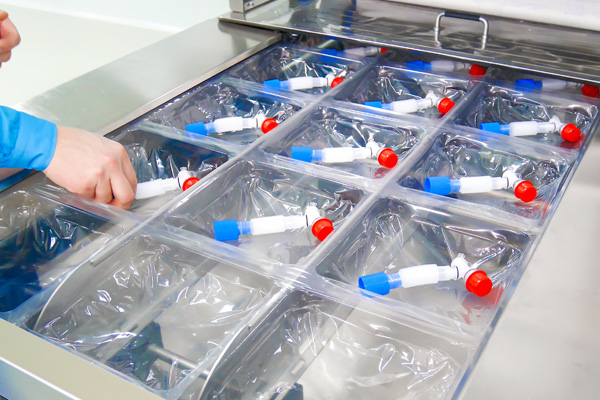

Simplimatic Receives Order For PWB Automation For Ventilators

read more >>>

New Financing Program Promotes Rapid Growth

read more >>>

Ramped Up College Recruiting Builds Engineering Team

read more >>>

Simplimatic is Headed to Semicon West

read more >>>

An Industrial Christmas Poem

read more >>>

On Behalf of the entire Simplimatic Team, Merry Christmas!

read more >>>

Five Shocking Facts This Halloween about PCB Production

read more >>>

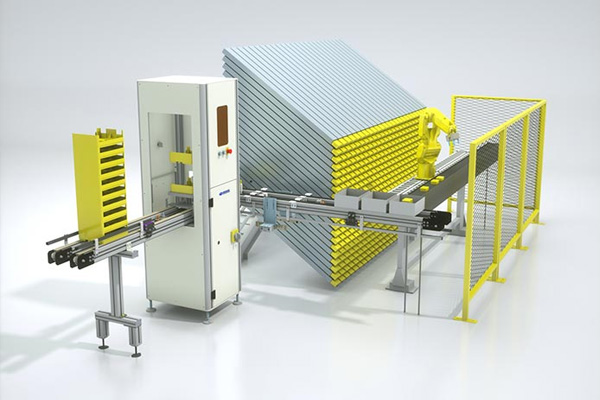

Simplimatic Palletizing Robot Offers Advanced Error Recovery

read more >>>

Simplimatic Hire Marks Expansion into Latin American Markets

read more >>>

Top 5 Reasons to Visit Simplimatic at Pack Expo Las Vegas

read more >>>

Simplimatic Prepares for SMTAi 2017

read more >>>

Simplimatic Gains Attention at IPC APEX

read more >>>

Simplimatic’s Innovative Conveying and Robotics Solutions Headed to IPC APEX

read more >>>

Simplimatic Simplifies Electronic Assembly

read more >>>

Simplimatic Designs the Latest in Automated Lens Handling

read more >>>

Simplimatic Dazzles at Pack Expo 2016

read more >>>

Simplimatic Adds New VP of Packaging Sales

read more >>>

Unlimited Scalability with Simplimatic’s new 20-Lane Pill Dispensing Bed

read more >>>

Simplimatic sponsors local Bionic Eagles

read more >>>

Simplimatic Custom Automation Increases Speed For Danish Customer

read more >>>

Simplimatic Joins Total Solutions Program.

read more >>>

Smart and Simple Solutions for Household Product Manufacturers

read more >>>

Simplimatic Expands Robotic Capabilities with Dramco Acquisition

read more >>>

New Digital Content Developer at Simplimatic

read more >>>

Simplimatic Partners with Leading Robotics Distributor

read more >>>

Simplimatic to Build Expansive Manufacturing Facility in Forest, Virginia

read more >>>