Simpli-Flex® 83mm Tabletop Conveyor

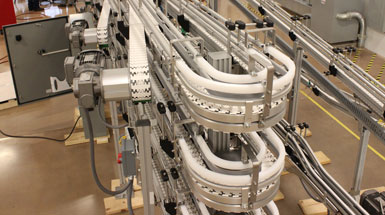

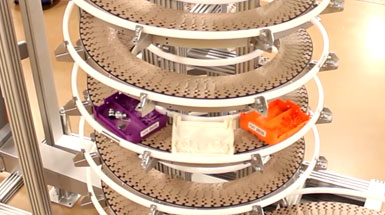

Simpli-Flex tabletop conveyor is a modular system designed to reliably transport packaged goods, cartons, pucks, pallets, and other materials through the many phases of manufacturing and packaging. Built with strong 6063-T6 extruded aluminum, Simpli-Flex conveyor provides users with multiple beam widths and chain options to guarantee an easy-to-implement, custom-tailored material handling solution.

Simpli-Flex conveyor provides unsurpassed versatility with its reconfigurable design and modular components. System components and options include:

- Modular Frame Design– Horizontal Bends, Vertical Bends, Wheel Turns, Conveyor Beam

- Guide rails – Fixed or adjustable to suit high-mix environments

- Variable Mounting – Single-leg, dual-leg, or ceiling-hung support

- Multiple Drives – Direct, intermediate, transmission, parallel transfer, powered transfer, wrap, catenary

- Numerous Chain Types – Finger top, open top, friction top, semi-closed top, steel top, fully-closed top, gripper top, and flighted top

Designed as an expandable conveyor system, Simpli-Flex is available in nearly any length with thousands of possible drive, chain, guide rail, and accessory combinations. Simpli-Flex orders are typically custom-tailored to each individual customer. For additional product information, or to order Simpli-Flex 83 mm Modular Tabletop Conveyor, request a quote button below.

SKU: Simpli-Flex® 83 MM Table Top Conveyor

Aluminum extrusion for quick assembly, reconfiguration, and the addition of accessories | Low-cost, high-performance modular product guide system | A wide variety of conveyor chain styles | Durable construction | Low-friction wheel turns | Heavy-duty drive and idle assemblies | Typical applications include: blow molding, personal care product handling, pharmaceutical and prescription fulfillment, consumer product, automotive component assembly, packaged food products, and beverage.

- Pre-engineered components make Simpli-Flex a very versatile conveyor system, allowing the greatest amount of layout capability achieved with the least amount of component variation

- Various structural options including single-leg, dual leg, and ceiling-hung

- Large variety of chain options including finger top, open-top, semi-closed top, fully-closed top, flighted, friction top, steel top, gripper top, and roller top

- Many drive options including end drive, intermediate drive, parallel drive, combined drive units, catenary drive, wrap drive, and more

- Closed or open style conveyor beams available to suit multiple applications

- Internal and external T-slots used for mounting turns, drives, idle ends, brackets, crossbeams, devices, and to splice additional lengths of beams

- Reusable, expandable, and easy to work with

- Hardware mounting slots in the aluminum extrusion allow for quick and easy component-to-component assembly using common hand tools

- Allows for manual product stops, positioning, elevating, and accumulating

- Easily accommodates workstations

- Can include bar code identification and readers, radio frequency tags, or read/write devices to easily track product throughout the manufacturing process

- Backed by worldwide service and support from Simplimatic Automation

- Designed and built in the USA