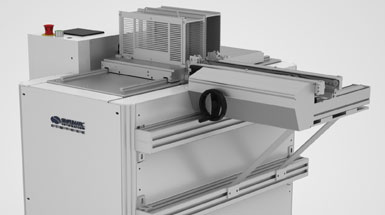

Cimtrak® Edge Belt Lift Gate

Cimtrak Edge Belt Lift Gates are used to create a pedestrian aisleway in a production line which is typically closed. Product is conveyed across this machine until an operator presses the “open” button, which pauses the up-line flow and unlocks the gate. The gate features a counter-weighted electromagnetic lock, designed for easy opening.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Description

Allen Bradley® PLC | Emergency stop and reset controls | hand crank width adjust | Fully counter-weighted gate | Electromagnetic lock | Adjustable gas shocks and stops | Typical applications include: creating an aisleway in a long production line, low-cost solution for openings on a pallet return loop |Electricity required: 110/220 V AC. 3 A, 50/60 Hz

- Allen Bradley® PLC

- Emergency stop and reset controls

- Hand crank width adjust

- Fully counter-weighted gate

- Electromagnetic lock

- Adjustable gas shocks and stops

- Typical applications include: creating an aisleway in a long production line, low-cost solution for openings on a pallet return loop

- Electricity required: 110/220 V AC. 3 A, 50/60 Hz

Options

- 50” lift gate features a 28” opening

- 60” lift gate features a 38” opening

- Power width control (PWC)

- Precision-cut, proprietary aluminum extrusion frame

- Other customer-specified voltages available

- Optional docking tooling for downline machine

- High-speed DC motors can move a five-pound product at 70 ft/min

- Leveling foot pads with 3/4” threaded steel rod and locking nut for height adjustment

- Hinged access panels

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA