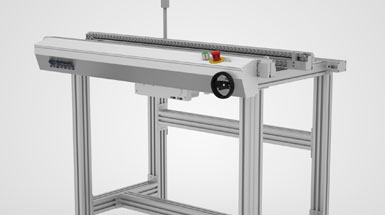

Cimtrak® +/- 90° Slide & Turn Conveyor (Servo Motor)

The Cimtrak Slide & Turn Conveyor system is capable of rotating product 270° about a vertical axis. Depending on line configuration, product can be introduced or discharged from any side including same side in and out transfers.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

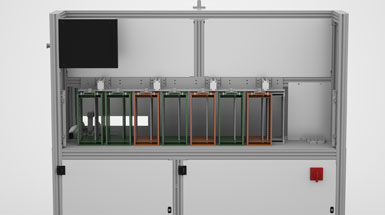

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Pneumatic, motorized, or closed-loop servo positioning system | High-speed DC stepper motor conveyor | Interlocked cover with alarm | User-configurable routing options | ESD conveyor belts | Hand-crank width adjust | Typical applications include: 90° turns, production line merging or diverging, good board and bad board routing, and changes in fixed rail orientation | Electricity required: 110/ 220 V AC, 5 amps, 50/60 Hz.

- Power width control (PWC)

- Product scanning

- Dual lane

- Belt width of either 3 mm or 5 mm

- Tooled width adjust

- Slide width adjust – cam locks on width adjust

- Center justified width adjust

- Turn units can be reconfigured for different material handling routes

- Other customer-specified voltages available

- Hinged doors, slide-mounted electrical panel, top-access door, and easily-removable vanity covers improve access to machine

- Zero-clearance edge guides eliminate the danger of boards becoming jammed under the edge guide

- Standard Allen-Bradley controller system can be expanded to include network capability

- Ultra-low backlash gear reducer

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA