Medical Device

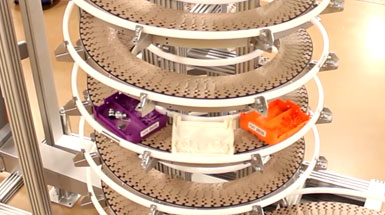

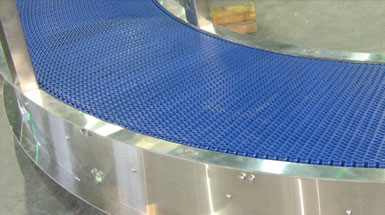

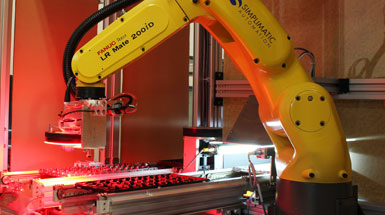

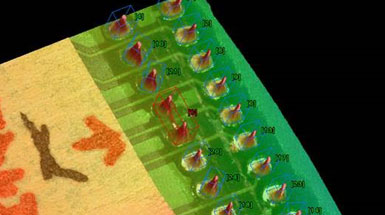

Backed by our commitment to excellence, we supply custom material handling systems, robotics, and automation systems to medical device manufacturers worldwide.

Our custom assembly cells and systems assemble, convey, pack, and palletize durable medical equipment (DME). We can help your organization automate production for a myriad of DME, such as insulin delivery devices, ostomy supplies, vision care, wound treatment products, and diabetic testing and care supplies.