The month of haunted houses, pumpkins, scary movies, and trick-or-treating is upon us, but let’s turn on the lights at your manufacturing facility and dispel frights that are common to electronics material handling and automation for printed circuit board production.

1.) Manual Board Handling Should Be Just A Spooky Ghost Story

Manual product handling can be the beginning of a frightening tale which ends in minimized throughput. Although manual tasks in a production line have their place, moving boards and fragile electronics has never been easier (or more cost effective!) with Simplimatic’s broad range of Cimtrak® edge belt conveyors, and custom automation products. Simplimatic makes transporting, flipping, buffering, and more, easy, all while protecting your ESD-sensitive products. Even moving boards from one line to another on your floor can be achieved using Simplimatic’s custom mobile robotic automation systems. Your dream of a streamlined production system, can be our treat to you this Halloween season!

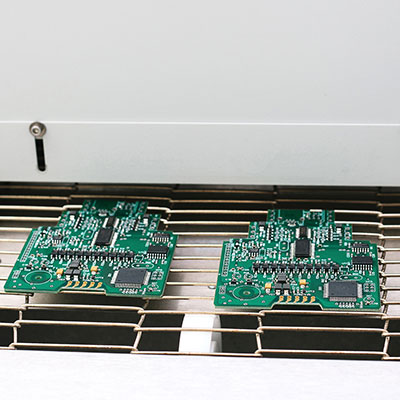

2.) Singed Circuits Are Simply Sinister For PCB Quality

Every printed circuit board manufacturing process is subject to slow downs and stoppages. If your production line lacks automated buffering capabilities, there is a chance that your PCBs might find themselves in the eternal flames of the reflow oven. No manufacturer likes to see a Printed Circuit Board meet a fiery demise, and Cimtrak® FIFO/LIFO buffers from Simplimatic alleviate that risk. Available in multiple board capacities, fitting a variety of standard (up to 18″ x 20″) and non-standard board widths, Cimtrak® Buffers are a reliable solution for ensuring PCB peace of mind between stoppage-sensitive processes.

3.) Line Changeover Can Strangle Streamlined Board Manufacturing

The thought of lot size one operation certainly haunts contract manufacturers around the globe. The process of adjusting dozens of production systems is certainly a bone-chilling idea that has the potential to cripple even the most streamlined PCB production. Simplimatic’s line of Cimtrak® board handling systems with powered width control (PWC) are designed to make line changeover for PCB production simple and smart. With the touch of a button (or scan of a barcode), your line can magically adjust guide rail width to accommodate multiple board sizes allowing for maximum production potential no matter the lot size.

4.) Semiconductors Are Susceptible to Seasonal Shock

Fall and Winter are seasonably dryer months on the PCB production floor and can lead to an excess of static buildup. Seeing sparks fly on your PCB processing line could mean the destruction of valuable components, and hidden production quality issues that can linger for years to come. When it comes to your electrostatic-sensitive devices, let our systems take charge…literally. Our entire line of Cimtrak® material handling and automation systems are designed to dissipate damaging electrical charges to ensure the only shock you’re dealing with is how easily Cimtrak® systems are integrated your existing equipment.

5.) Maintenance and Service Fees For PCB Handling Can Be Frightening

Are maintenance and service costs haunting you day and night? Simplimatic can remove that fear with the industry leading reliability and longevity of our Cimtrak® Edge Belt Conveyor Products. By maximizing printed circuit board production downtime, and maximizing board throughput, you’ll see a huge return on investment freaky-fast. Out Cimtrak® products have an average lifespan of over 15 years with routine system maintenance.

If you’re ready to leave the fright behind and enjoy an improved production line using Simplimatic’s Cimtrak® electronics products, contact Simplimatic using the form below. Wake up from the nightmare that is PCB manufacturing without Simplimatic, and get back to the finer things of this season, like pumpkin spice lattes, pumpkin pie, pumpkin-flavored cookies, pumpkin donuts, and of course, trick or treating (for pumpkin-flavored candy, obviously).