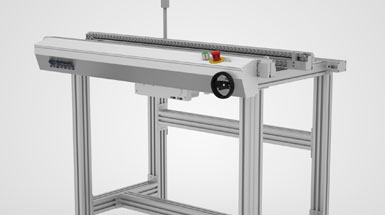

Cimtrak® AOI Reject Conveyor

Simplimatic’s Cimtrak AOI Reject Conveyor allows printed circuit board manufacturers to easily isolate bad or rejected boards from production. Board rejection is based on up-line process input, typically provided by Automated Optical Inspection (AOI) systems.

This conveyor system uses pneumatically-controlled channels to carefully lift and remove PCBs from the line for secondary human inspection and rework without slowing down or stopping production. The SMEMA-compliant system also features a board return function to gently reintroduce isolated PCBs back to production.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Cimtrak® Edge Belt Reject Conveyors are designed to quickly and efficiently remove bad boards from manufacturing processes without causing any line stoppage. The system uses pneumatically operated fingers to lift bad boards from the edge belt conveyor and allow good boards to continue traveling down line.

- One drive with variable speed of 1-70 ft/min

- Includes EMO and ESD grounding receptacles

- Hand crank width adjust 2-18”

- 37 in elevation, adjustable +/- 2 in

- Cimtrak® programmable width control adds programmable width to above unit, width value can be entered using local HMI, and encoded stepper controller is used for width movements

- Optional scalloped table and footrest

- Optional overhead light and accessory frame

- Electricity required: 110 VAC, 5 amps, straight blade plug

- Allen Bradley PLC

- Independent DC stepper conveyor motors

- 3 mm edge contact, 5 mm overall edge clearance

- ESD timing belts

- 0.8 m overall length

- Right to left transfer, front fixed rail

- SMEMA interface

- Hinged lexan cover, not interlocked

- Precision-cut, proprietary aluminum extrusion frame

- Other customer-specified voltages available

- Pneumatically operated fingers lift the bad board up between guides, creating room underneath for good boards to pass under

- 2 inch top side clearance for good boards under lifted bad boards

- Includes release button to return board to conveyor

- Includes pneumatic control panel

- Includes SMEMA logic upgrade to accept signal from up-line machine or pass signal down line

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA