MES Integration

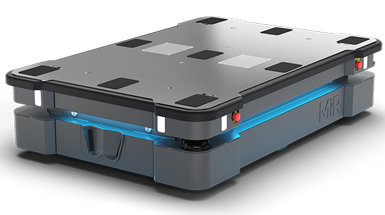

MIR 100

MIR 250

MiR 600

MIR 1350

The future of autonomous mobile robots (AMRs) is here. AMRs are designed to optimize productivity in logistics and manufacturing operations. AMRs make your employees more efficient by allowing them to focus on higher-value activities, while shortening lead time, reducing the risk of bottlenecks, and optimizing safety.

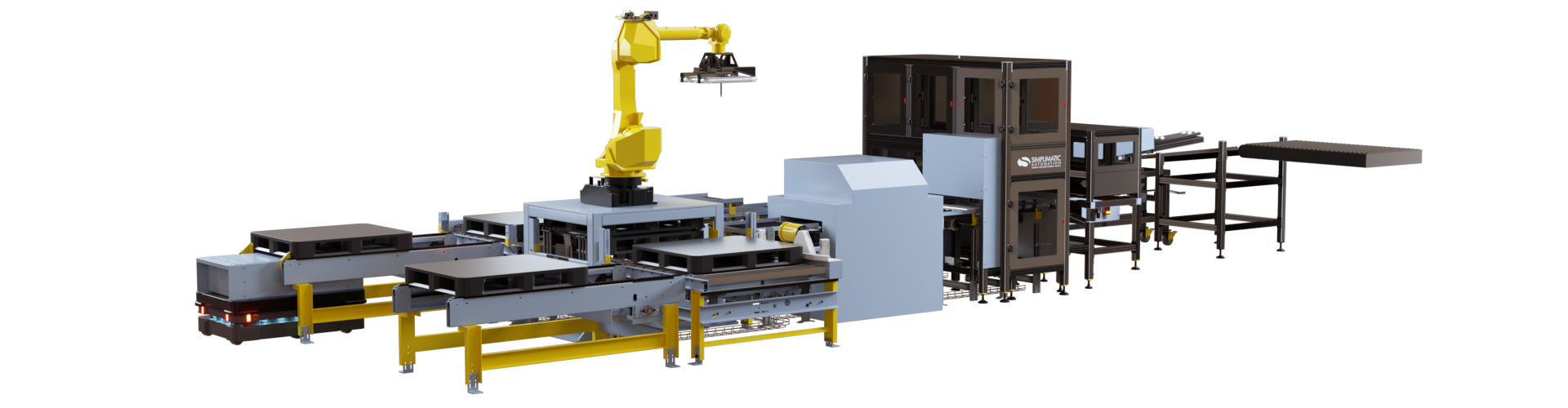

Simplimatic Automation is an integrator of MiR (Mobile Industrial Robots) and can supply customers with a mobile platform and advanced collaborative robotics to automate nearly any manual task. An AMR from Simplimatic can serve many functions for manufacturers and can be equipped with custom end-of-arm tooling (end effectors) to aid in tasks such as material delivery, screw driving, picking and placing, adhering, sorting, and more. AMRs can perform similar tasks at multiple locations on a line utilizing just a single robot, maximizing return on investment, and minimizing initial automation costs. AMRs use cameras, laser-based navigation systems, and collaborative robotics to operate around already-existing features, including plant personnel in a manufacturing environment.

Simplimatic is a Certified System Integrator for MiR.