Cimtrak® Board Cleaner

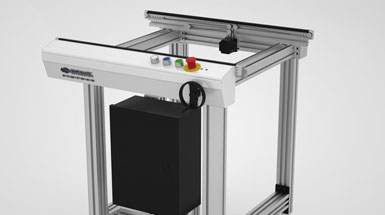

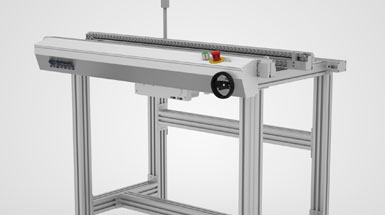

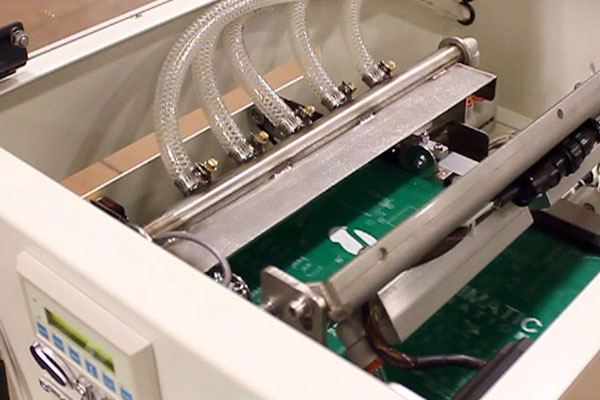

Simplimatic’s Cimtrak Board Cleaner is designed to function as a pass-through for Printed Circuit Boards (PCBs) and other electronic assemblies. While moving through the machine, a set of air knives remove particulate and other foreign material (FM) from sensitive electronics. This system is also outfitted with a cleanroom-certified vacuum to remove the debris from the system to avoid re-entrance onto the line. This machine also features a static-dissipative Cimtrak Edge Belt Conveyor to transfer product safely by its edges.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak® conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Cimtrak® Board Cleaners are designed to eliminate particulate and other debris from sensitive electronics | 24 inches overall length | One drive, variable speed 1-70 ft/min | Typical applications include: removing particulate from PCBs and other electronic devices

- 24 inches overall length but can be customized to suit specific customer requirements

- Allen Bradley PLC

- 5 mm product edge contact using Cimtrak® Edge Belt Conveyor

- Independent DC stepper conveyor motors

- Air knife includes power supply and ionizing bar

- Includes fully assembled pneumatic enclosure

- Air knife includes two 6 in Exair model Auper Ion Air Knives

- Includes EMO receptacles

- 37 in elevation, adjustable +/- 2 in

- Precision-cut, proprietary aluminum extrusion frame

- Precision-cut, proprietary aluminum extrusion frame

- Other customer-specified voltages available

- SMEMA 1.2 interface

- Features edge belt hold-down rollers to secure the board during blow off