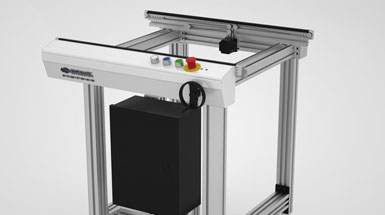

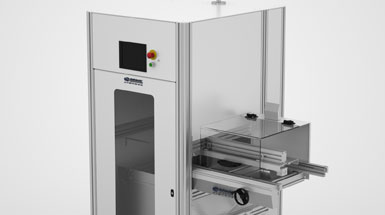

Cimtrak® Board Elevator

Cimtrak Board Elevators are designed to accommodate positive or negative elevation changes within a production line. Elevation changes within 16” (41 cm) are most common, but the standard unit can accommodate a change of up to 50” (127 cm). Longer strokes for this product are available. These systems are most commonly used for in-feed and discharge of wave solder systems, but they have also been actively used for pallet re-feed systems.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

High-speed DC stepper motor conveyor | Hand crank width adjust | High-precision THK linear guides | Adjustable shocks and load positions | ESD conveyor belts | AB PLC | Typical applications include: Raising or lowering production lines to clear obstructions or wall openings, raising or lowering production to facilitate operators at seated workstations | Requires 110/220 V AC, 3A 50/60 Hz | Air requirements are OFA, 80 PSI, 0.2 CFM

- Power width control (PWC)

- Right-to-left transfer

- Longer (taller) stroke available

- Tooled width adjust

- Zero-clearance edge guides eliminate the danger of boards becoming jammed under the edge guide

- Other customer-specified voltages available

- Step-through mode allows the user to pause at each step of the loading process, which is helpful during set up and changeover

- Adjustable stops and shocks allow the elevator positions to be adjusted

- Even major changes in load/unload positions can be made by the user

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA