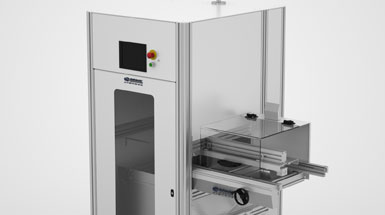

Cimtrak® Board Inverter (Servo Motor)

The Cimtrak Board Inverter is an edge belt conveyor system that is designed to rotate flat panel products 180° around a horizontal axis. The system can also pass product through without inverting; accept, invert, and discharge from the same side; or invert and pass. Invert cycle time is approximately four seconds.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gap between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides a light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Closed-loop servo invert mechanism | High-speed DC stepper motor conveyor | One-piece machined aluminum carriage plates | Hand crank width adjust | Ultra-low backlash gear reducer | Bi-directional conveyor | Slide-out electrical panel | Typical applications include: In-line transition from top-side to bottom-side manufacturing and flip and return for islands of automation, such as conformal coating | Electricity requirement: 110/220 V AC, 3A, 50/60 Hz.

- Touchscreen User Interface

- Power width control (PWC)

- Dual Lane Conveyors – adds second lane for increased throughput

- Tooled width adjust – secures adjustable rail with tooled brackets to lower cost and work well in low-mix production

- Large-frame version – increases capacity to 18” x 24” board (450 mm x 600 mm)

- Belt width of 3 mm or 5 mm

- Servo-controlled invert system allows the user to fine tune the invert speed and stop location

- Other customer-specified voltages available

- Dual-belt drive system holds product from the top and bottom, ensuring the product is successfully transferred and safely inverted

- Zero-clearance edge guides eliminate the danger of boards becoming jammed under the edge guide

- Standard Allen-Bradley controller system can be expanded to include network capability

- Optional powered width control feature allows the operator to specify an exact conveyor width by entering it via thumbwheel

- Ultra-low backlash gear reducer

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA