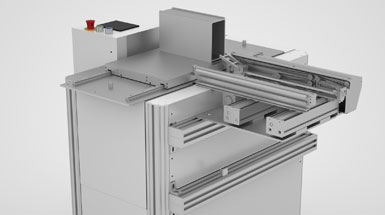

Cimtrak® Shuttle Gate

Cimtrak® Edge Belt Shuttle Gates allow products to be conveyed across an opening in a production line. This allows operators to pass between machines in a line instead of walking around the end of the line. The shuttle remains retracted until a board is ready to transfer. The average cycle time is seven seconds.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak® conveyor features zero gap between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides a light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Contact a member of the Simplimatic sales team for more information or to request a quote for a Cimtrak Edge Belt Shuttle Gate.

SKU: Cimtrak Shuttle Gate – Model 3260

- Zero-gap edge guides eliminate the danger of boards becoming jammed under the edge guide

- Other customer-specified voltages available

- Precision-cut, propriety aluminum extrusion frame

- Extruded frame and conveyor rails allow accessories to be easily added and positioned

- All Edge Belt Connecting Conveyors are bi-directional

- High-speed DC stepper motors can move a five-pound product at 70 ft./min

- Modular conveyor rails allow the length of the conveyor to be significantly increased or decreased at a minimal cost

- No driveshafts to align or guard

- Typical applications include: Conveyance of PCBs, Auer boats, and JEDEC trays between manufacturing processes; buffering and metering; acting as a platform for inspection, product ID, manual placement, and other processes.

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA

- Power width control (PWC)

- Dual lane

- Right-to-left transfer

- Rear-fixed rail

- Tooled width adjust – requires tools to adjust

- Slide width adjust – cam locks on width adjust

- Wireless SMEMA communication-eliminates need for wireway across aisle