Cimtrak® Flat Belt Conveyor

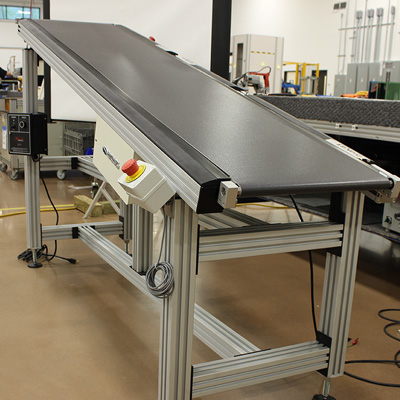

Simplimatic’s Cimtrak® Flat Belt Conveyors are used to safely convey a variety of electronics and ESD-sensitive products between manufacturing processes. These conveyors provide full support across the bottom of the product while ensuring an electrostatic dissipative conveying process. Cimtrak® Flat Belt Conveyors can be used as a simple means of spanning large distances or these systems can be outfitted with sophisticated controls, cooling fan banks, guide rails, integrated vision and other accessories. These systems are most commonly used to accept board from wave solder systems.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak® product features:

- Wide Anti-static belt – 18″ wide, variably lengthed fabric anti-static belt is used for conveying sensitive electronics

- Reliable DC stepper motor – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

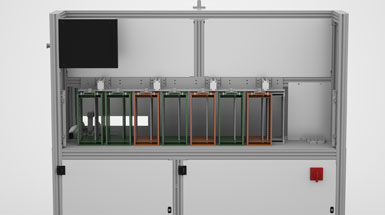

Cimtrak® Flat Belt Conveyors safely convey a variety of PCBs, JEDEC trays, Auer boats, and pallets |

- High-powered DC motor

- Emergency stop and reset controls

- 18” wide, high-friction ESD conveyor belt

- Zero-gap edge guide

- Stainless steel conveyor bed

- Sealed ball bearings

Typical applications include: Conveyance of PCBs, pallets, Auer boats, and JEDEC trays between manufacturing processes; buffering, indexing, or pacing products; acting as a platform for inspection, wave solder discharge, or cooling

Additional Options

- PLC control (required for indexing functions or most operator controls/interfaces)

- Length (3-20 ft)

- 12 ” Width (custom widths available)

- Light tower

- Fixed stop at discharge end

- Footrests, armrests, work tables, and work station accessories available

- Incline/decline configuration (for wave solder off loading)

- Cooling fan banks

- Guides

- High temperature conveyor belt or chain

- Precision-cut, proprietary aluminum extrusion frame

- Other customer-specified voltages available

- Extruded frame and conveyor rails allow accessories to be easily added and positioned

- High-speed DC motors can move a five pound product at 66 ft/min

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA