Robotic Cell Screwdriving

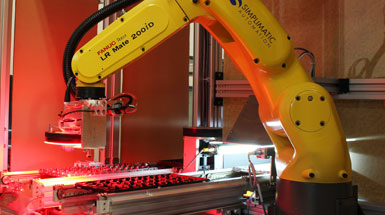

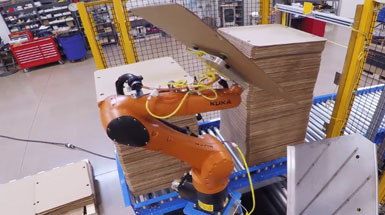

Simplimatic Automation’s modular robotic cell provides manufacturers with a simple in-line solution to automate the repetitive screw driving process in assembly and manufacturing typically performed by hand or via non-reconfigurable hard automation.

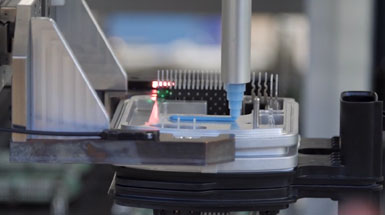

Our Robotic Screwdriving system easily automates the assembly process of multi-part components during manufacturing. This system utilizes custom end-of-arm tooling (end effectors) to pick and place individual components and fix them together using metallic, plastic, and composite fasteners. This intricate system improves production quality and line reliability while simultaneously increasing production throughput.

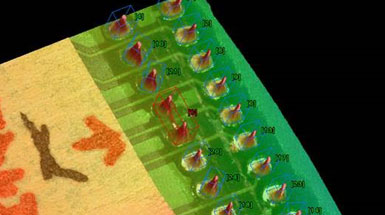

Simplimatic’s material handling and automation products help customers create a seamlessly running manufacturing line. Depending on project requirements, the Simplimatic® screw driving cell can utilize either a fixed-position screwdriver or a vision-guided screwdriver. The application method depends greatly on product geometry or screw driving complexity. This multi-axis screw driving robot supports multiple recipe types to easily accommodate multiple SKUs on a production line.