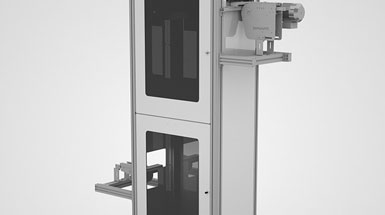

Optitrak™ Tray Stacker / Destacker

The highly customizable Optitrak Tray Stacker/Destackers from Simplimatic automatically load or unload batches of ten trays at the beginning and end of process cells. Operators simply load stacks of ten trays onto the ergonomically friendly in-feed conveyor and the Optitrak tray destacker will singulate trays and deliver them to the next process smoothly and reliably. At the end of the process, the Optitrak™ Tray Stacker will automatically stack individual trays and discharge a stack of ten.

Simplimatic’s line of Optitrak products are designed to carefully handle a variety of ophthalmic products such as optical trays filled with eyeglasses, lenses, and other eye care items. Each Optitrak™ product can be integrated with Simplimatic’s Simpli-Flex® table-top conveyor for a more complete final packaging and shipment line. Optitrak products can also be integrated within a customer’s pre-existing line layout to suit a variety of optical factory and warehouse environments.

Optitrak product components include:

- Rugged Frame Design – Optitrak products are constructed using strong 6063-T6 extruded aluminum

- Compatible – Can easily be paired with Simplimatic’s Simpli-Flex conveyor

- Customizable – Infeed, discharge, tray stack sizes and other features can be customized based on customer need

For additional product information, or to order Simplimatic’s Optitrak Elevator/Lowerator, request a quote.

SKU: Optitrak Tray Stacker / Destacker

This highly customizable piece of equipment can accommodate various tray sizes and stacking configurations while having the ability to add accessories to allow the unit to expand for any customer facility expansion or company growth | Typical applications include: handling and buffering optical trays.

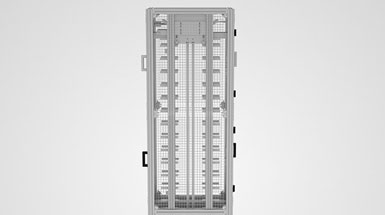

- Various size stacks of trays can be accommodated

- Multiple stack positions include stacking in the tray stacker, in-between the stacker and destacker, and within the destacker

- The stacker/destacker combo unit has the ability to accumulate five stacks of 10 trays each

- The conveyor design utilizes a twin belt design to ensure the tray stacks remain stable as they move through the process

- The base stacker module has interface capability (I/O) with the optical process machine to dispense one tray at a time when needed

- Can include fixed end stop and pin stops to singulate stacks to downstream equipment

- Accessories such as bar code and RFID readers can be mounted on the single-tray discharge end for future tray routing capabilities

- Independent control system

- Structurally-rigid, clear anodized aluminum extrusion

- T-slots allow the fastening of standard brackets or other attachments

- Powder-coated painted parts offer extended equipment life

- Adjustable height-leveling feet

- Unit comes pre-assembled

- Backed by worldwide service and support from Simplimatic Automation

- Designed and built in the USA