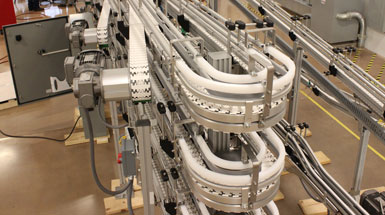

Simpli-Flex® HD Spiral Elevator

The Simpli-Flex spiral elevator is designed as a space-saving method to reliably change the elevation of packaged goods, cartons, pucks, pallets, and other materials during the phases of manufacturing and packaging. Built with a blend of 6063-T6 extruded aluminum and mild steel, the 36″ diameter Simpli-Flex spiral elevator offers the convenience of a smaller size with great strength.

The conveyor is equipped with corrosion-protected, long-lasting RexHiPro roller chains, eliminating the need for frequent part replacement. System components and options include:

- Multiple Discharge Positions – Inline, 90 degree, 180 degree, and 270 degree

- Numerous Chain Types – Finger top or friction top

Simpli-Flex Spiral Elevators provide customers with continuous product flow during line elevation changes. The system operates with a 36” centerline, the smallest spiral footprint in the industry. The Simpli-Flex Spiral Elevator is easily adaptable for different products and is available in an optional stainless steel washdown configuration depending on project requirements. For additional product information, or to order a Simpli-Flex Spiral Elevator, request a quote button below.

SKU: Simpli-Flex Spiral Elevator

36” centerline diameter with larger diameters available | 12” pitch per 360-degree | Available with smooth or top grip | Elevator or lowerator styles available | Typical applications include: Providing an elevation change, buffering products between manufacturing processes, adding cycle time to a line, and accommodating space limitations by elevating product to an additional raised conveyor system.

- 36” centerline with larger diameters available if needed

- Available with smooth or grip top flight, depending on application

- Elevator or lowerator styles

- Fixed (standard) or adjustable guides available

- Conveyor and base frame available in aluminum or stainless steel

- Available in four discharge configurations: inline, 90 degrees, 180 degrees, 270 degrees

- Smallest spiral footprint in the industry with a 36” centerline diameter

- 12” pitch per 360-degree coil

- Mild steel with powder coat construction

- Backed by worldwide service and support from Simplimatic Automation

- Designed and built in the USA