2D & 3D Vision Inspection

Today’s manufacturing market is hypercompetitive, and companies cannot lag behind when it comes to the quality and consistency of their product. To keep up with quality standards, 2D and 3D machine vision is the most efficient and accurate way to inspect your products and/or materials. Many crucial components need to come together in order to use machine vision inspection; sensors within your vision camera, the processing hardware and software algorithms to render your materials and communicate the results back to you. In order to integrate these technologies, you need a proven integrator with years of experience in vision inspection across many different industries like Simplimatic.

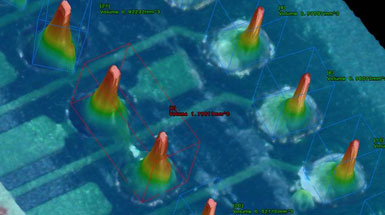

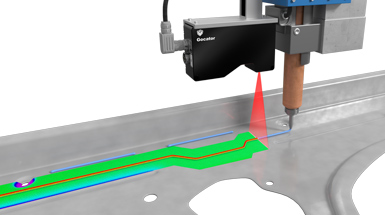

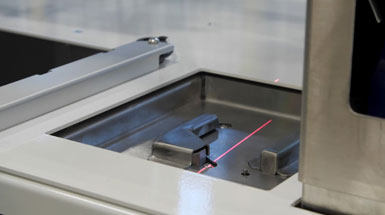

Vision systems can automate complex and/or mundane visual inspection tasks within your manufacturing line. These visual quality inspections detect positioning, verification, measurement, identification, and flaws. Depending on what your company’s quality control standards and requirements are will determine if we will use 2D or 3D machine vision inspection. 2D camera sensors view an area based on 2 dimensions, length and width. 3D camera sensors look at length, height, and width (depth).

3D vision inspection is optimal for volumetric measurements, parts inspections, linear measurements, identification, and bin picking applications for electronics, semiconductors, and factory automation.

Benefits of machine vision solutions:

- Quality

- Traceability

- Efficiency

- Accuracy

- Higher capacity