Accumulation Table

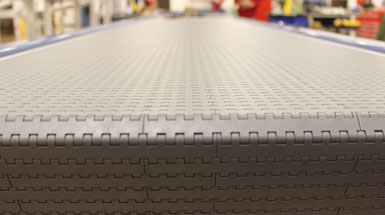

Mat Top Conveyor

Sanitary Mat Top Conveyor

Simplimatic® beverage conveyor systems are primarily used to convey plastic bottles, aluminum cans, glass bottles, and other large items that require a heavy-duty frame and chain/belt to accommodate significant line back-pressure.

Simplimatic’s Mat Top conveyor systems are a collection of high-quality, conveyor components designed to reliably transport bulk goods between processes during bottling, packaging, assembly, and manufacturing. Utilizing multiple frame types and chain styles, Simplimatic’s Mat Top conveyor provides customers with the ability to select a bulk-material handling system that is perfectly engineered to solve a project’s mass conveying needs.

Simplimatic has built the framework necessary to ensure lifetime spares, service, and support are available for all Simplimatic products installed around the globe. Contact Simplimatic today for more information on Simplimatic’s Mat Top Conveyor systems or to request a quote.