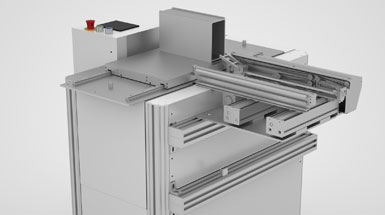

Cimtrak® JEDEC Tray Flipper

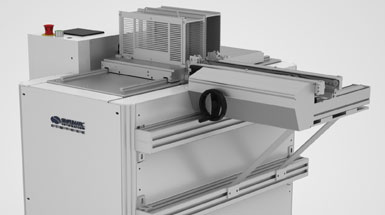

Cimtrak® Micro Magazine Loader

Cimtrak® Micro Magazine Unloader

Our semiconductor conveyor systems can optimize your operations and maximize your productivity. We have an agile conveyor product line that will seamlessly integrate into your existing facility.

We develop semiconductor conveyor products for chip assembly, testing, packaging, and research and development. Our robust equipment has numerous applications for JEDEC trays, auer boats, FOL carriers, and other pallets used in backend-of-chip and downstream manufacturing processes.

Keep your line running and meet your business goals with our customized products, solutions, and systems.