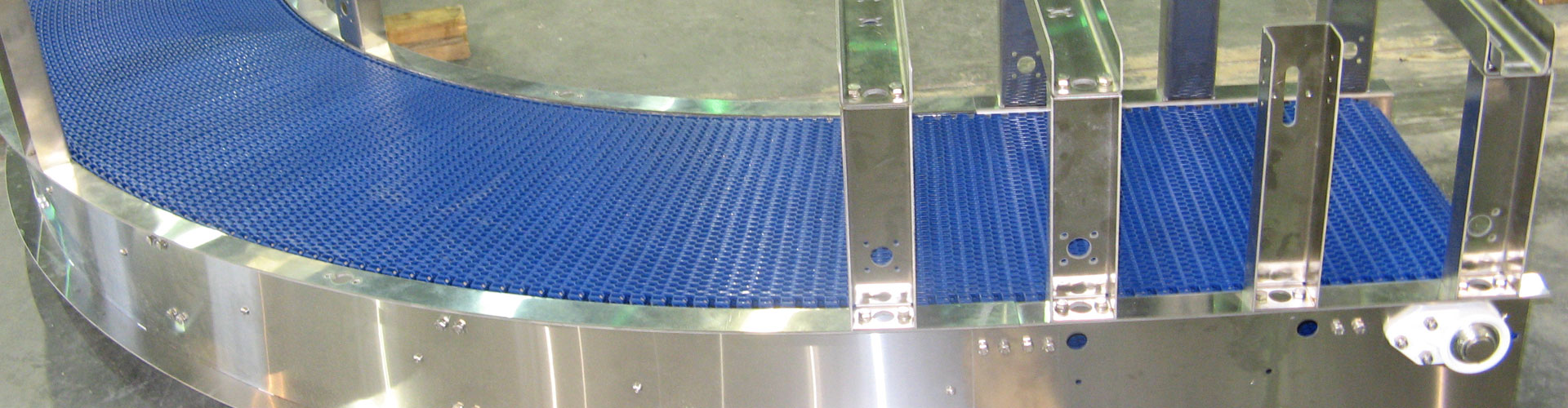

Accumulation Table

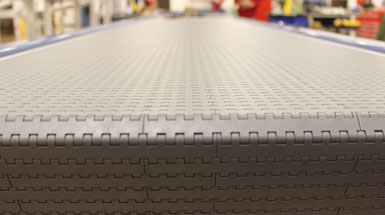

Mat Top Conveyor

Neck-Guided Air Conveyor

Sanitary Mat Top Conveyor

Single Filer Conveyor

Simplimatic’s mat top conveyor systems are a collection of high-quality conveyor components designed to reliably transport bulk goods between processes during bottling, packaging, assembly, and a wide range of other manufacturing tasks. Utilizing multiple frame types and chain styles, Simplimatic’s mat top conveyor provides customers with the ability to select a bulk-material handling system that is perfectly engineered to solve a project’s mass conveying needs.